Description

Features

Advanced Programming Capabilities:

The MX800 can be easily re-configured using MXTOOLS, a technical Diagnostic and Alignment tool. MXTOOLS software runs on a standard PC and uses a Graphical User Interface (GUI) allowing the adjustment of over 100 microprocessor controlled parameters.

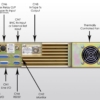

| 485-520MHZ |

Specific Hardware Setup

Simple hardware based configurations or adjustments can be done quickly and easily by the Technician using jumper links and analog multi-turn pots.

User Self-Monitor and Diagnostic Capability

The MX800 incorporates Built In Test Equipment (BITE) as standard, so as avoiding the need for any external costly monitoring units. The built in Forward and Reflected RF Wattmeter is as accurate as most modern Test Equipment.

Power Supply System

By adhering to the 13.8V DC industry standard, the MX800 retains the benefits of simplicity, efficiency and low cost of ownership. Inferior 28V designs suffer from reduced Transmitter VSWR rudgeness and the added cost and inefficiency of DC to DC converters.

Complete Remote Accessibility

A internal Ethernet interface (T58) Option provides data access to the MX800 Base Station/Repeater using Internet/Intranet TCP/IP Protocols. Using the MXTOOLSRD software, remote control and diagnostics monitoring of the MX800 can be performed

Rugged Performance

The MX800 is designed and built without compromise to exceed industry standards and all international specifications. Is also capable of withstanding extreme temperature conditions and is engineered for maximum reliability. A compact yet efficient heatsinking system maintains the highest possible levels of service in adverse environments. Other inferior designs vent hot air through internal sections exposing core components to increased temperatures. The MX800 solves these problems and others by passing all hot air along the outside of the chassis and away from neighboring equipment.